Coffee roasting defects and how to prevent them

by Willem Boot

Imagine you’ve roasted your favorite Colombian beans with a new profile and while cupping the roasted samples something just doesn’t taste right. In this column I’d like to discuss the most common roasting defects, and strategies how to prevent them.

Scorching

This type of defect occurs when coffee beans are roasted at excessive temperature levels usually at the early stage of the roasting cycle. As a result, you can often notice tiny little burned marks, resembling blisters, on the exterior flat or rounded surface of the beans. Flavor notes: harsh, astringent, smokey and burnt. To prevent scorching, I recommend reducing the charge temperature of your beans.

Tipping

Similar as “scorched” but the burn marks will show up at the tips of the beans. Tipping occurs when the roasting drum has hot spots or when the drum rotates too fast. Hot spots can be prevented by cleaning and/or calibrating the burners of your machine. Basically all Giesen roasting machines offer the ability to adjust the rotation speed of the drum. To prevent tipping, reduce the rpm’s (rotations per minute) of your machine by 5 points at a time and look for improvements.

Baking

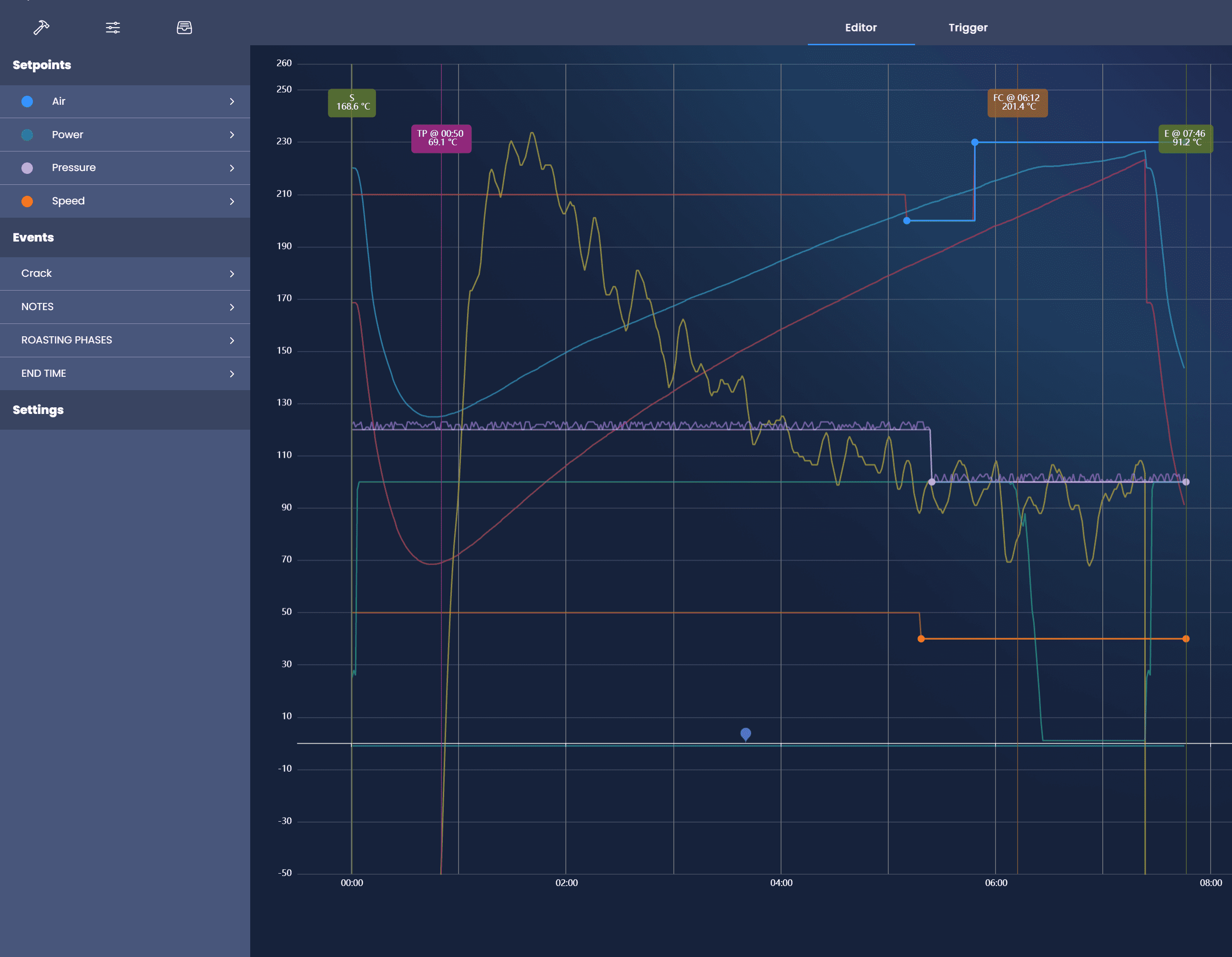

Baked coffee tastes dull and lacks acidity. Often, it appears as if the coffee lacks character and soul. This defect occurs when the bean temperature of the beans doesn’t rise sufficiently or stalls during the final minutes of the roast. To prevent baking, make sure to monitor the Rate of Rise (RoR) at all times. Fortunately, almost all Giesen machines are equipped with built in RoR monitoring.

Underdeveloped

Alfred Peet, founder of Peets Coffee, introduced more than 35 years ago the concept of dark roasted coffee. During the past 10 years we saw the proliferation of third wave coffee roasting styles. Many of these avant garde roasters take pride in roasting their beans with a minimum level of development. As a result, the caramelization of sugars isn’t optimal and the acidity of the coffee can be quite sharp, lacking essential sweetness. To prevent underdeveloped beans, install proper lights next to the roasting machine and stay away from profiles that have insufficient development. If the first crack starts at 8 minutes then you should allow for a minimum development time of 45 seconds.

Too dark or overdeveloped

In the USA, the legacy of Alfred Peet resulted in a relatively large number of specialty coffee consumers who love dark roasts. It’s up to you whether or not you’ll facilitate the addiction of these clients. Dark roasting styles inevitably enhance the sensation of body with flavor notes reminiscent of smoke, bakers chocolate and leather, often with a drying, astringent texture. To prevent the coffee from overdeveloping, limit the development time of the roast to 20% or less. If the first crack starts at 9 minutes, you should finish the roast before or around the 11th minute. The newest Giesen roasting software, Giesen Profiler, is a very effective tool to prevent underdeveloped or overdeveloped roasted coffee beans.

Quakers

This is an interesting category of roasting defects because the root cause lies with the cultivation of the coffee cherries. Quaker beans have a peanutty flavor lacking sweetness and lacking the actual characteristics of the coffee in general. Because of growing conditions, quakers lack distinct sugars and as a result these beans remain very light during the roasting process. Apart from sorting quakers by hand after roasting, this roasting defect is difficult to prevent as there’s no way to recognize quakers in a batch of green coffee beans.

Quality Inspection and Cupping Protocols

There is no doubt that a stringent cupping routine will help you to improve the consistency of your roasted coffee. Besides inspecting the quality profile of your roasted beans, I recommend documenting for each coffee type the target flavor profile, which should be compared against the production results using effective cupping protocols. For example, after each shift of roasting, the roaster operator should taste at least 2 cups per roasted batch and compare the intensity of the key parameters of the coffee’s flavor profile (acidity, body, sweetness) against the targeted level. Some companies actually involve all roaster operators in daily tasting sessions, which enables the roasting staff to make effective assessments of their own performance, which will improve consistency in roast output and –in the end- strengthen customer satisfaction.

Best regards, Willem Boot.

Monthly Giesen Webinar:

Join us live on every last Friday of the month at 09:00 Pacific Time (PT)

Or 18:00 Central European Time (CET).

This Post Has 6 Comments

Great! Thanks for putting these on.

wow, great article. gained lots of knowledge after reading your article. I have a business your article will help me for sure. keep up the good work.

Good Information Thanks For Sharing

Great post. Thanks for sharing some prevention tips for coffee with us, I gained lots of knowledge through this post. Keep sharing more.

I roasted my coffee beans once out of curiosity and since then I am a home roaster. I never buy pre-roasted – it just tastes different. Way better to roast them home – if you know what you do. Thanks for sharing the ideas.

Thanks for your post. It helps me a lot in improving my roast skills