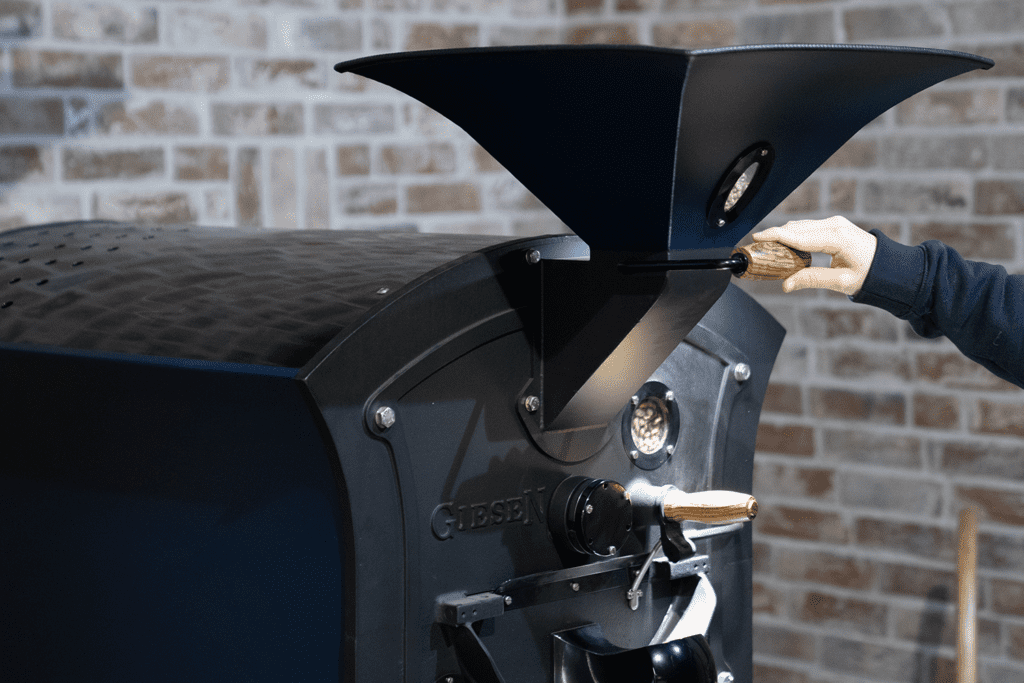

In the monthly Giesen webinar, Willem Boot, David Sutfin, and Marcus Young cover topics various topics related to coffee roasting. The topics we focus on in this Giesen webinar: We start off by explaining the function of the Hz / RPM setting on the Giesen machines. For starters, this function changes the speed the drum in your machine rotates. But what does this function exactly do? By testing, Boot Coffee came to the conclusion that the drum speed accelerates the roasting profile significantly. Higher drum speed will translate to more convection heat. Also, the beans will be pushed to the outside walls of the drum which means the conductive heat will be increased as well.

What are we going to focus on in this Giesen webinar #5:

- The difference in changing the drum speed setting makes

- What will change in terms of flavor when we utilize different drum speeds?

- Live roasting session

Changing the drum speed on your Giesen machine

Marcus Young says that changing the drum speed may have the most impact when looking at the changes you can make on your machine during roasting. At the beginning of a roast, it can be very difficult to follow a roast profile by changing your drum speed. Therefore, matching a profile by changing this factor can be very challenging.

| Batch No. | Drum speed | Airflow | Color | Color temp* | Roast time | Development time | Development time % | Weight loss |

|---|---|---|---|---|---|---|---|---|

| 1 | 60 | 140 | 58 / 71 | 300 °F 149 °C | 11:05 | 1:55 | 17.3% | – 15.7% |

| 2 | 60 | 140 | 58 / 71 | 300 °F 149 °C | 10:58 | 1:51 | 16.9% | – 15.8% |

| 3 | 50 | 140 | 58 / 69 | 305 °F 152 °C | 11:49 | 2:10 | 18.3% | – 15.5% |

| 4 | 40 | 140 | 58 / 68 | 335 °F 168 °C | 11:42 | 2:06 | 17.9% | – 15.8% |

| 5 | 40 | 175 | 56 / 66 | 329 °F 165 °C | 12:04 | 1:18 | 10.8% | -16.0% |

In the table above you can see that Willem and Marcus did some extensive testing on the differences in drum rotation. You can see how different indicators such as color, the temperature at color change, roast time, development time, and density were affected by the different drum speed and airflow settings. Check out the webinar video for the explanation Willem and Marcus give with every roasted batch.

Cupping the results

After discussing the table, Willem cupped the results from the different batches, check out the video to find out about his specific findings on the different batches and roast techniques. Therefore, the difference from going from a higher drum speed to a lower drum rotation can mostly be recognized in the acidity of the roast. Also, the sweetness is more prominent in the higher drum speed batches. Higher airflows mean that the acidity opens up much more, which indicates that more convection heat was able to enter the coffee. Marcus states that batch one and two have a very aggressive, almost harsh acidity. Since batch three was most close to the more common roast settings, this is the one Marcus liked the most.

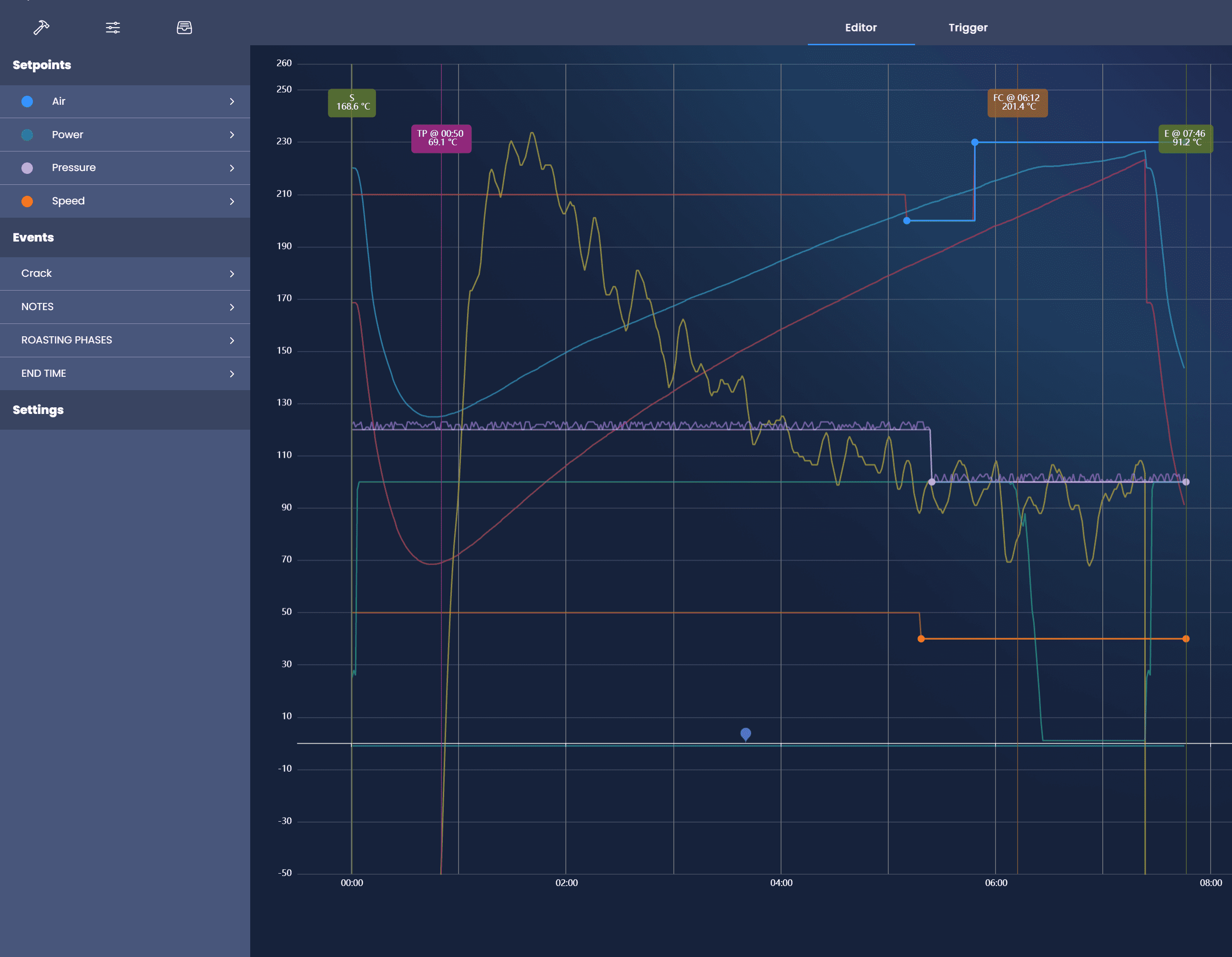

Live roasting

Time to roast! Before we actually start roasting, Marcus explains where in the Giesen Profiler software you can record the drying phase in your roast which will be indicated within the Profiler roast screen. With this roasting session, Marcus used the 70 Hz drum speed setting which is quite a bit higher than the standard setting and is the highest setting the Giesen WPG-1 will allow. We see that things happen faster than expected, but the roast was in full control. The quality of the first crack was more drawn out and subdued than what was expected. Experimenting with these kind of settings can be very interesting, especially when you are going to cup and test the results.

Question and answer:

Q: Is there a rule of thumb when it comes down to changing drum speed vs. smaller batch sizes?

A: Marcus Young says that you should approach changing drum speed with caution. A lower drum rotation with a smaller batch side could be beneficial to your result, since the contact time will be higher. Like with a lot of roasting techniques, this will be trial and error for your particular situation. Therefore, when you make changes in drum speed, make sure the steps in differentiation you take are small.

Q: Do you and Marcus have different preferences in drum speed when roasting different variants of coffee?

A: It all comes down to the nature of the bean. When beans are low in density and quite bold, these type of beans could benefit from lower drum speeds. At the same time, these type of beans could benefit from a lower air speed. Therefore, the benefit of Giesen machines is that these indicators (drum rotation and air speed) can be changed during roasting. You aren’t stuck with a fixed drum speed.

Q: What differences in settings do I need to make when using smaller side beans compared to larger beans?

A: Imagine if you charge your roaster with the same batch size. One roast was using a larger bean and the other was using a pea berry. Your turning point will come at a lower temperature with the pea berry. This because the pea berry has more surface area for the same mass of coffee than with a larger bean size. Therefore, each individual bean will absorb more energy.

The next webinar is on the 30th of October, where we will cover additional topics related to coffee roasting, and we will do a live roasting session. Of course, there will be plenty of time for Q&A as well.

Check out the Giesen blog articles here.