Giesen Webinar #1

This unique monthly webinar hosted by Willem Boot covers topics like the perfect profile and how to achieve this. Together with live roasting sessions and exploring the features and functionalities of our coffee roasters and related equipment. What follows is the recording and a summary of the Giesen Webinar #1 of 29th May 2020.

This first webinar is recorded at the Boot Coffee Campus, where Willem has a training center and where they also perform tests for Giesen. Also present in the webinar is David Sutfin, agent of North America and Canada who performs sales, service and support, together with Katie Cates.

Willems background is that he originates from the Netherlands, just as Giesen. He started roasting at the young age of 14 which has led him to climb the hierarchy on to roast on bigger roasters. Ultimately, he and his father and brother collaborated in their family business, The Golden Coffee Box. What was special about their way is that they focused on the single origin coffees, which was an unusual thing to do in the 1970’s. In their own way, they stayed ahead of the curve.

Willems relationship with Giesen started about 14 years ago, right when Giesen came out with their first roasting machine, the W6A. It felt amazing to control and manipulate the roast to his liking at any point in the roast. According to Willem Boot, this is what makes Giesen roasters so powerful.

Together with Marcus Young, the campus director at Boot coffee, David and Willem will help you to unlock some of the misunderstandings and mysteries in roast profiling.

What are we going to focus on in the first webinar:

- General features of the Giesen roasters

- Specific features of the control panel

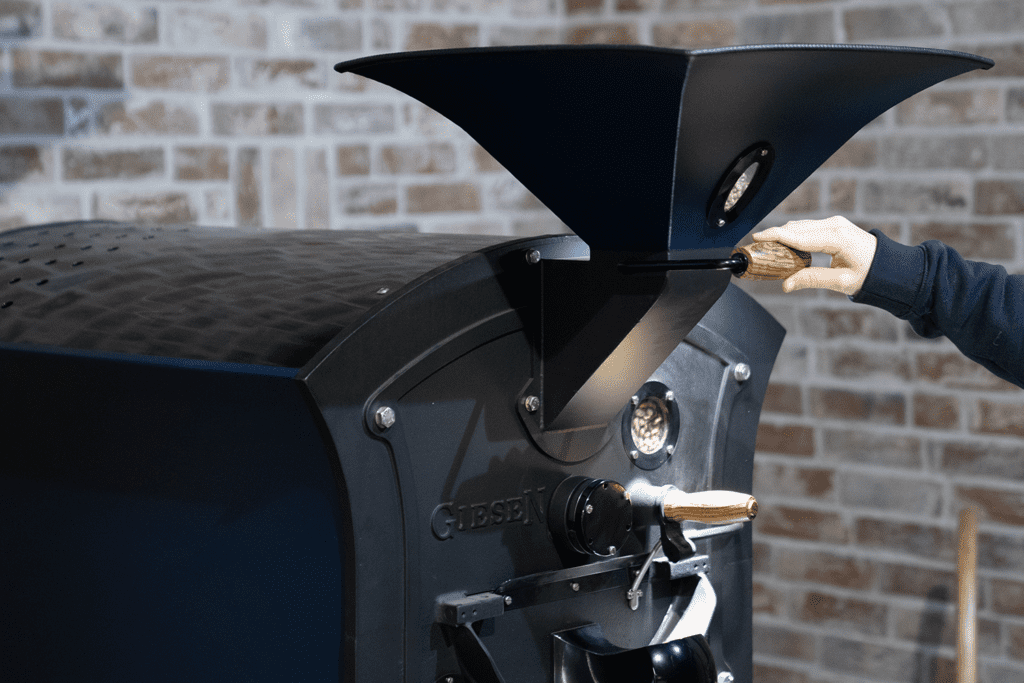

- Live roast with Marcus Young with a W6A

- Questions from audience

General features of Giesen roasters:

- Giesen has been operating in the US for about 12 years. Willem and Giesen have been involved since the first product launch.

- A unique benefit of a Giesen roaster vs other brand is how controllable the airflow is. Other brands also offer airflow control but Giesen took it to the next level. Airflow allows you to really navigate the roasting profile in terms of flavor.

- Giesen’s cast iron components which have the ability to absorb and radiate heat in a very gentle way.

Specific features of the control panel

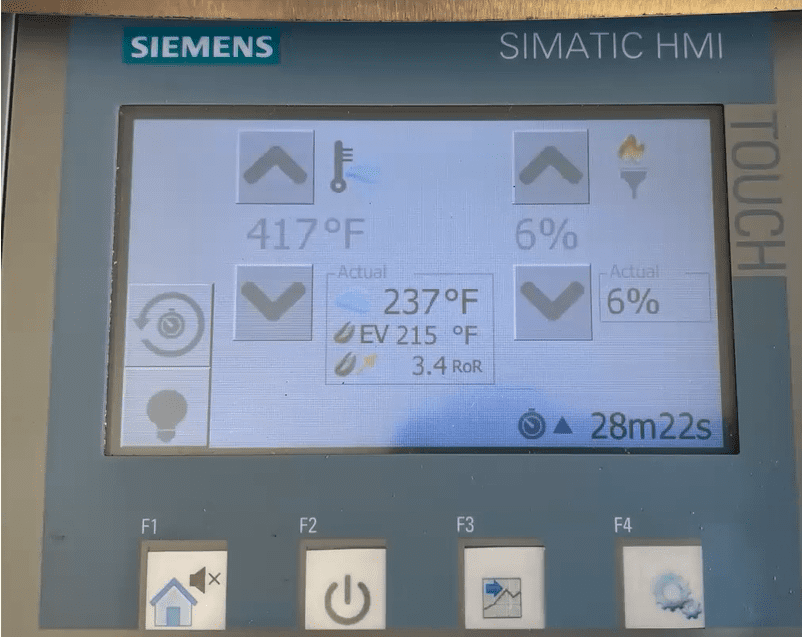

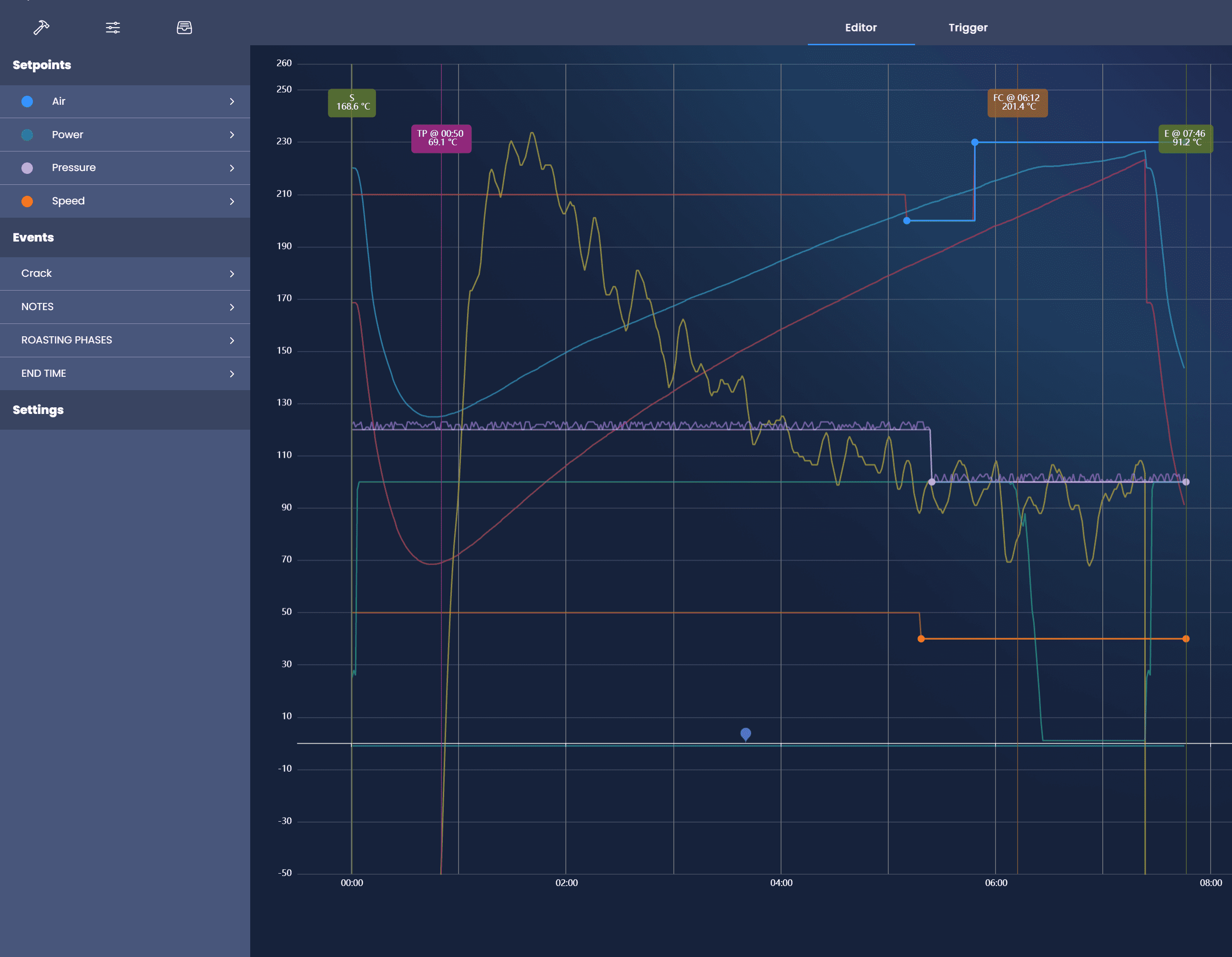

The control panel is one of the main panels to be working on your roast with. On top of that, there is also the Giesen Profiler which we will be working on in another session which is the 26th of June. This is the main interface where you can find the following data: Bean temperature, air temperature, the rate of rise, and the burner settings.

Air setpoint: I want to control my roast up to 417°F. In this case I will allow the Giesen to apply the setpoint (thermostat). The roaster will then strive to reach up to the air temperature of 417°F and while the temperature of the actual air temperature gets closer to that setpoint, the roaster will gradually modulate down its burner setting.

When would I want to use this setting?

- For creating consistent roasting profiles

- Preheating the coffee roaster

- Not using it (by still using it). Set the temperature to 450°F and focus on your other settings like power.

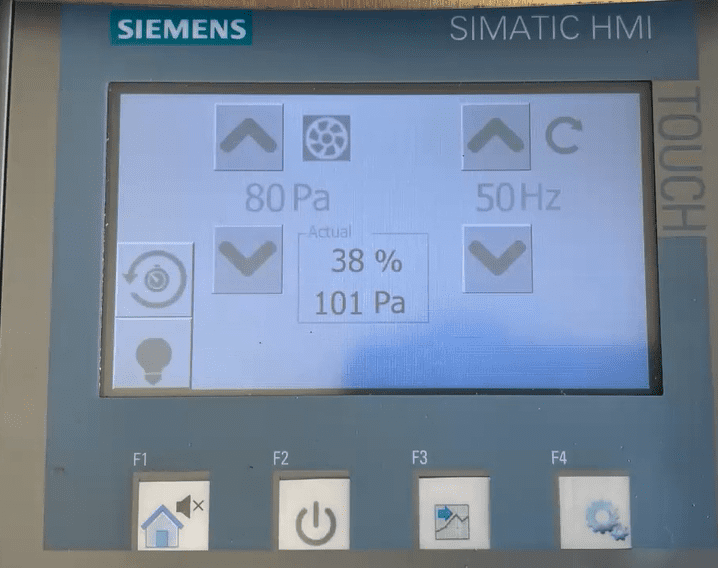

Air pressure:

Many other coffee roasting brands let you control the airflow by opening and closing a damper or by opening a fan or speeding up a fan. Giesen has a fan but it takes it one step further because there is an air pressure sensor in the return exhaust. That sensor is measuring the pressure inside the roasting machine.

In this example you can see the lowest Pa setting: 80Pa. Why would you ever use this setting? This is for when you want to roast a coffee with very little convection heat. The airflow will be minimal. The maximum setting is 220 (or even higher). This setting highlights specific nuances of the coffee that are driven by the acidity of the coffee. In Marcus’ roast the pressure is set at 120 Pa to drive more conduction earlier in the roast.

Live roast with Marcus Young

He is roasting coffee from Hacienda Coffee, a local importer and client of Boot Coffee.

- Reading your beans in size, color, texture, moisture content, density and characteristics;

- Create a strategy based on your readings which includes capacity, preheating, manual or auto burner control;

- Do you need to ‘soak’ coffee? Soaking is an approach where you’re starting very low, with little to no gas, letting the coffee get accustomed to the heat of the drum. If you have more delicate coffee, it’s a way to prevent scorching and other roast defects;

- Roasting outcomes and evaluation.

Q&A from Giesen Webinar #1:

In regards of the W15A I’ve tried using 110 and 120 Pa, but anything more than 60% gaspower makes the RoR really high? What is typical for the W15A?

You can consult the technicians of Giesen or David Sutfin to recalibrate the actual heat output of the burners. The Rate of Rise tells you how quickly you are going from one point in the roast to the end point. Right now, Marcus’ RoR is 10.6, this means that every 30 seconds the temperature increases about 10°F. This is an indication for how quickly you are going in your roast and to what degree you might want to power down your burner input. There is a fundamental dynamic between the RoR and your strategy about the power. That means that if your RoR goes absurdly high, it’s best to contact Giesen-certified technicians.

How can I use the airflow in the final stage to prevent a smoky flavor?

Smoky flavors develop because of the fact that coffee is generating its own heat which is eventually accelerating roasting smoke. Roasting smoke cannot escape quickly enough. An effective way would be to increase your Pa setting. The fan will then work harder to allow the access smoke to escape.

What affects does the profile have by an increase or decrease of drum speed?

The faster the drum rotates the more the beans are being pushed to the outer drum due to centrifugal forces. The beans themselves will also rotate faster from the back to the front of the drum. So, with more drum speed, you get more conductive heat radiating though the beans due to them touching the drum more. But you’re also getting more convection heat because of rotating speed of the beans. Willem Boot will record an entire webinar on the effects on drum speed.

Monthly Giesen Webinar:

Join us live on every last Friday of the month at 09:00 Pacific Time (PT)

Or 18:00 Central European Time (CET).

The Coffee Campus will start launching public Giesen specific one-day-workshops. They will be free to participate in but the capacity is limited. More information will follow.

Dit bericht heeft één reactie

Hey could I please be emailed when spaces for the roast webinar are up? Cheers!