The coffee roasting basics; how to roast coffee beans

Coffee. The journey starts with the green bean and ends up as the perfect beverage entirely made to your liking. Whether you like your coffee as a cold brew, dripped or filtered, espresso, or any other possibility, they all have one thing in common; it all starts with the green bean. In this article, we share the basics behind the process of roasting coffee beans. What steps does the green bean go through to eventually become that delicious roasted coffee bean we all know and love, and what’s the science behind it?

1. Drying the green beans

Since the green beans have a humidity of around 10%, we need to dry the beans before we start the actual roasting process. Since all the Giesen roasters are drum roasters, the beans need around 6 to 8 minutes to complete the drying process. Controlling the temperature of the roaster is extremely important at this point since you do not want to burn the beans in the drying process. When this stage flows into the next, the temperature of the beans will be around 160 °C.

2. Browning the beans

The browning stage is the stage wherein the aromas of the beans will start to develop. In other words; we convert the aroma precursors to aroma compounds. Even though this stage follows up on the drying stage, the beans haven’t completed the drying process. During the browning process, we see the Maillard reaction taking place. This means the natural sugars and amino acids within the coffee beans start to react and create a distinctive color and flavor characteristic to the coffee bean. Naturally, the roast starts to slow down after the reaction. Some roasters want the process to slow down since it can help to further develop the flavor profile of the bean. Obviously, this all depends on your preferences as a roaster. During the browning we see the occurrence roasters refer to as the first crack. This means the beans are expanding which brings us to the next stage.

3. Roasting coffee beans

This is the stage where you as a roaster can fully shape the taste profile you are looking for. Roast too fast, and you will create a coffee that tastes smoky and is too sharp. Roasting trial and error is the key to find that perfect profile.

“This is the stage where you as a roaster can fully shape the taste profile you are looking for.”

The expanded beans now start to release all the heat that was built up during the previous stages, which is called exothermic heating. The roasting stage leads up to the wanted aroma compounds that you want. In this blog we explain the differences between light, medium and dark roasts.

3.1 Roast degree

The roast degree is one of the, if not the most important factor to use when indicating your roast. The color of the bean tells you a lot when looking for that perfect roast. Lightly roasted beans can have a sour, acidic taste while dark roasted beans have a more raw, bitter taste. Also, lightly roasted beans are known for their fruitier taste while dark roasted beans often have a somewhat burnt taste. This is possible because lightly roasted beans contain the organic compound hydroxymethylfurfural which gives the lightly roasted beans their fruity flavor. This compound, however, breaks down when the roasting process goes further which results in the burnt taste dark roasted beans have. Basically, we can assume that lightly roasted beans bring out the pure coffee taste better. It is easier to compare light roasted beans with each other than dark roasted beans.

3.2 Roast time

The roast degree has the biggest role when it comes to determining the definitive taste of the bean. The roast time, however, has an important role in the process as well. The guiding principle here is that the cohesion between all the stages is the most important. Roast fast and you create more aroma compounds but risk burning the beans. When you roast slow, you have more control over the flavor development of the beans. For example: when you want to create a blend with less acidity to be used for espresso, slow roasting may be a good idea. This because acids have more time to break down when you give them more time during the roast.

“The guiding principle here is that the cohesion between all the stages is the most important.”

As mentioned before, it all comes down to your preferences when roasting coffee beans. As the beans expand, they will harden and as a side effect, release so-called ‘chaff’. Chaff, if you will, can be compared to the skin of the coffee bean. Removing chaff manually can be a bit of a hassle which is why we developed an external cyclone, but more about that in the next stage.

4. Cooling the beans

After roasting we cool the beans. An important step in the basics of roasting coffee since the beans need to be cooled as soon as possible for the roasting process to stop. The cooling process is something you don’t have much control of; you release the beans. They enter the cooling sieve and the cooling process begins. Like mentioned before, the beans must be cooled within 4 to 5 minutes to ensure that the roasting process does not continue. When the beans are cooled, that marks the end of the roasting process.

5. Generated waste products

When we are done roasting coffee beans it’s necessary to get rid of the waste products that were created during the process. Our external cyclone is an accessory that takes care of the chaff that arose while roasting. Since the external cyclone collects the chaff, the beans that enter the cooling sieve are already separated from the chaff and can be processed immediately after cooling. In addition to physical waste, unwanted emissions are also created. To take care of this we offer various solutions; the Giesen Afterburner being one of them. This device is designed to burn the polluting by-products for a second time. This way, we reduce the smoke and smells significantly compared to their previous state. The afterburner is suitable for the bigger roasters, from the W30A and up. For the smaller roasters like the W1, W6, and W15 series we offer a solution as well; the SFE filters. These filters reduce the smoke and smell but work differently. The units contain an electrostatic filter and absorb particles that pass through the mechanical filters in the roasters.

6. After roasting coffee beans; how do you test your results?

To rate the roasted coffee most roasters use a procedure called cupping. Cupping is one of the more well-known ways of proofing your roasting results. This process relies on the skills and experience of the person who tastes the coffee. The process includes sniffs and slurps, all to get a clear picture of the taste you’ve created.

“As you can imagine everyone has their workways and professional secrecies to create their unique blend.”

How people do the cupping sessions exactly is different to every roaster. As you can imagine everyone has their workways and professional secrecies to create their unique blend. It is completely up to you as a roaster how you fill in your sessions and which aspects and outcomes are most valuable to you.

7. Roasting coffee beans; in summary

Our goal was to explain the basics that you will go through when roasting coffee beans. Understand that every roaster has their own preferences, working methods, and materials which means a lot of the described steps may vary depending on the roastery you visit. This makes the journey to the perfect roast so interesting; it isn’t a one-way process and to a roaster, the journey may be just as exciting as the eventual product itself!

Please share with us how you started your own coffee roasting journey in the comments!

Dieser Beitrag hat 13 Kommentare

What is optimum roast time on W6?

How many air adjustments during the roast? range

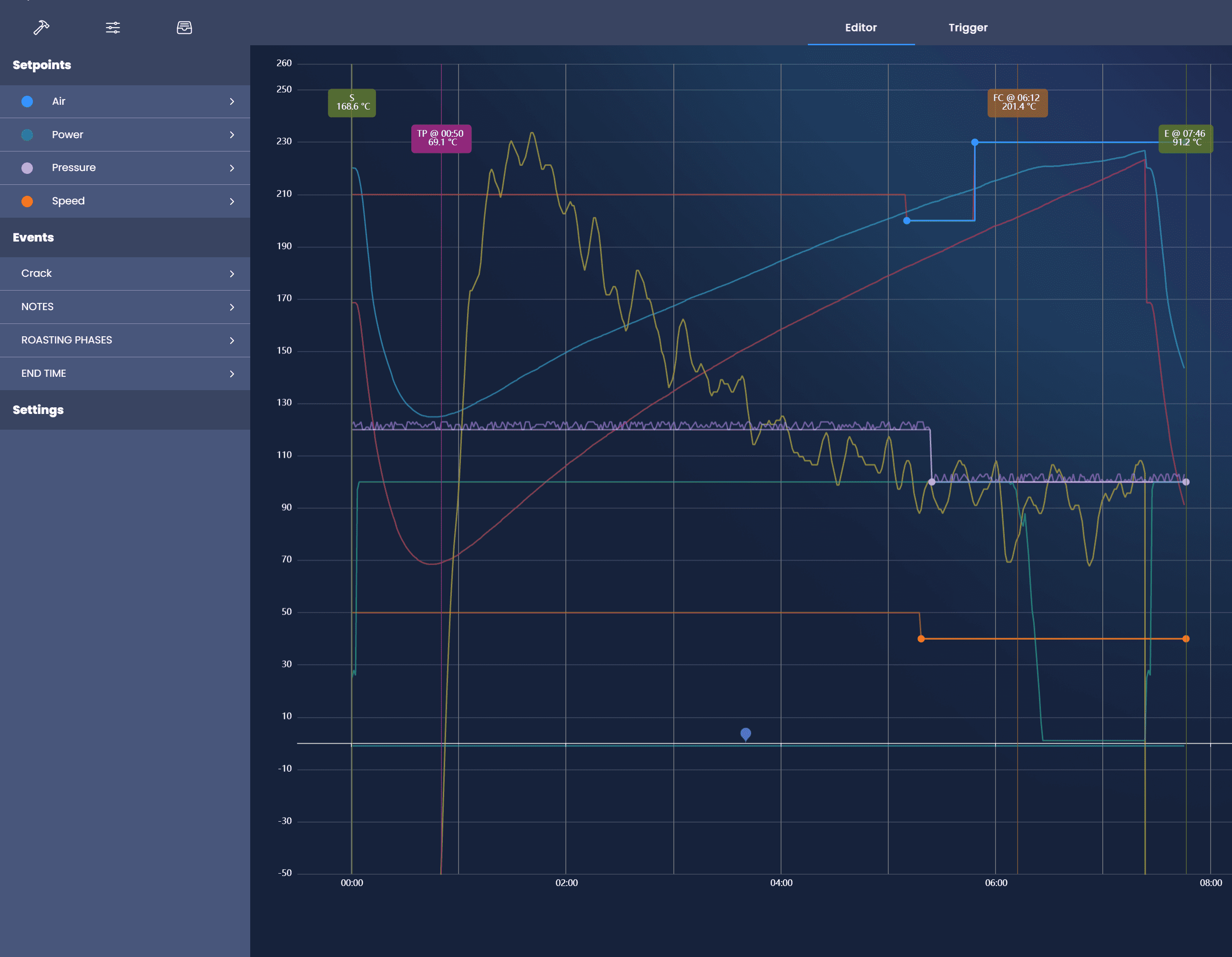

Can you show some curves with real data?

thank you

There really isn’t an optimal roast time. Because this depends on many variables, batch size, type of coffee, your environment, and of course the tastes you’re trying to develop while roasting. Maybe in another blog post, we can show you some curves with real data but my advice would be to just try and adjust your profile along the way based on your own experience.

Dear Shauni, I would like to ask about the Giesen profilervideo. On the video in the dryingphase I notice beantemperature is 13,2 celsius or fahrenheit? I just imagine getting the profiler will make RoRfeature easier to control but is the ror an averagetemoerature in endotherm phase bf 1. crack or can I consider it very precise so that when I roast want ror on 8 celsius pr minute I will just lower or increase the burner to reach 4 celsius every 30 seconds? I know that I also must dose the burner correct according to amount of beans I drop to reach TP2-3minutes

And the airflowcontrol. What is the outerlimits in pascal on w15 and w1?

I normally roast filter with ascend from crack is active 12-14 beantemperature degrees and espresso 18-21 degrees? How much will this change when increasing underpressure to remove the boring taste if coffee?

All tge best

Good lesson 👍

Very helpful thank you

Thank you!

We roast on W6, love that roaster. Right now working on “soak”, “flick and Crash” experimental .

Can you post some of yours optimum curves?

or Can we talk about pressure profiling?

might be interesting for audience

We actually have 2 posts about pressure profiling written by our ambassador Willem Boot. You can find them here: https://www.giesen.com/pressure-profiling/ und https://www.giesen.com/coffee-roasting-airflow-control-part-2-by-willem-boot/

Great post! Thanks for sharing.

Loved it. I put it on top of my coffee. Like a shot of espresso.

Excelente publicación, gracias por compartir

Other blogs say faster roast less acidic but more bitter, long roast less bitter more acidic

Hi Dave, thank you for your comment. Know that coffee is a complex product that many people have knowledge about, but also a product that many people have different opinions about. The same is true for the coffee-roasting world. People have their own experiences and theories, which keeps the coffee world interesting, challenging and exciting! In the case you outline, it may also have to do with the coffee used, the conditions, the fermentation or drying process of the coffee, and so on.