Creating a balanced and intriguing coffee blend can be very challenging and requires ample planning, persistence, and patience. At the beginning of my coffee career, I consumed and tasted single-origin coffees only. My dad founded our family’s coffee company in The Netherlands under the name The Golden Coffee Box. He had decided that single-origin was the only way to go and as a result, this became the mantra of our company. When customers would inquire about our blends, then my dad would simply tell them to purchase a few appealing single-origin coffees and to create their own blends at home. Basically, he would refuse to sell any blends whatsoever.

Coffee blending in the US

In the US, in the 1980s and 1990s, coffee blends became synonymous with cheap tasting coffee products. Often laced with Robusta beans. At that time, it seemed as if blends existed for the prime purpose to find a suitable place for the so-called “fillers”, inferior coffee types and qualities which are generally cheap to purchase as green coffee. And with the right recipe, these coffee components could quietly disappear in the overall flavor profile of the coffee.

Third-wave blending

Fortunately, the third wave of specialty coffee changed this status quo quite dramatically. Popular blends like Dancing Goats (Batdorf & Bronson), Black Cat (Intelligentsia) and Major Dickinson (Peets coffee) won the hearts of coffee consumers and aficionados around North America. The new approach of blending incorporates a fundamentally different philosophy about creating coffee products.

To create great blends, you need great components

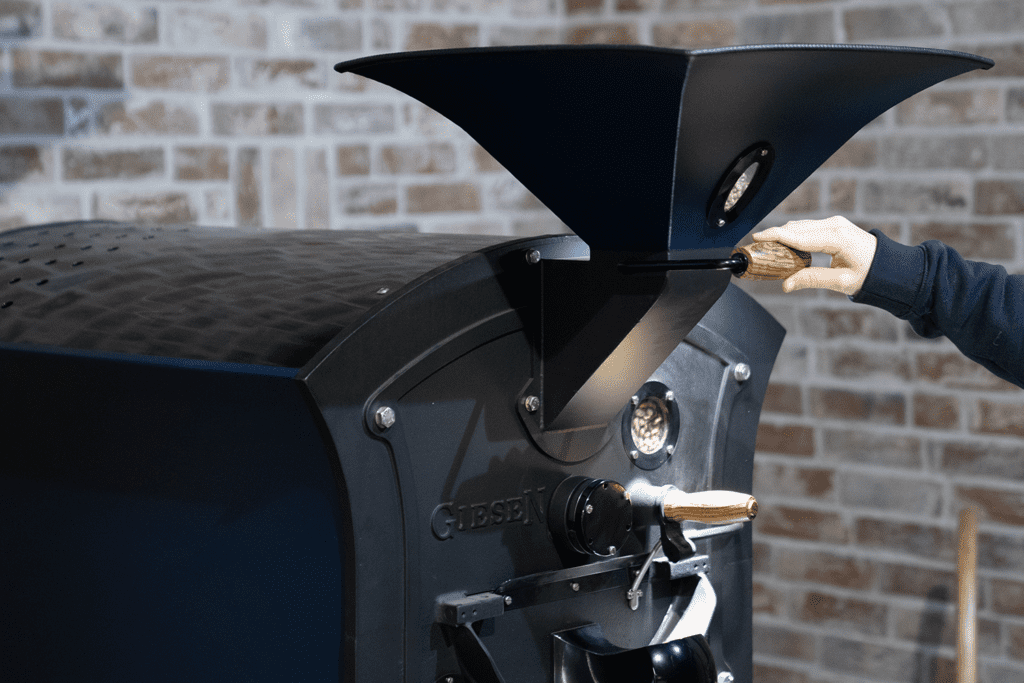

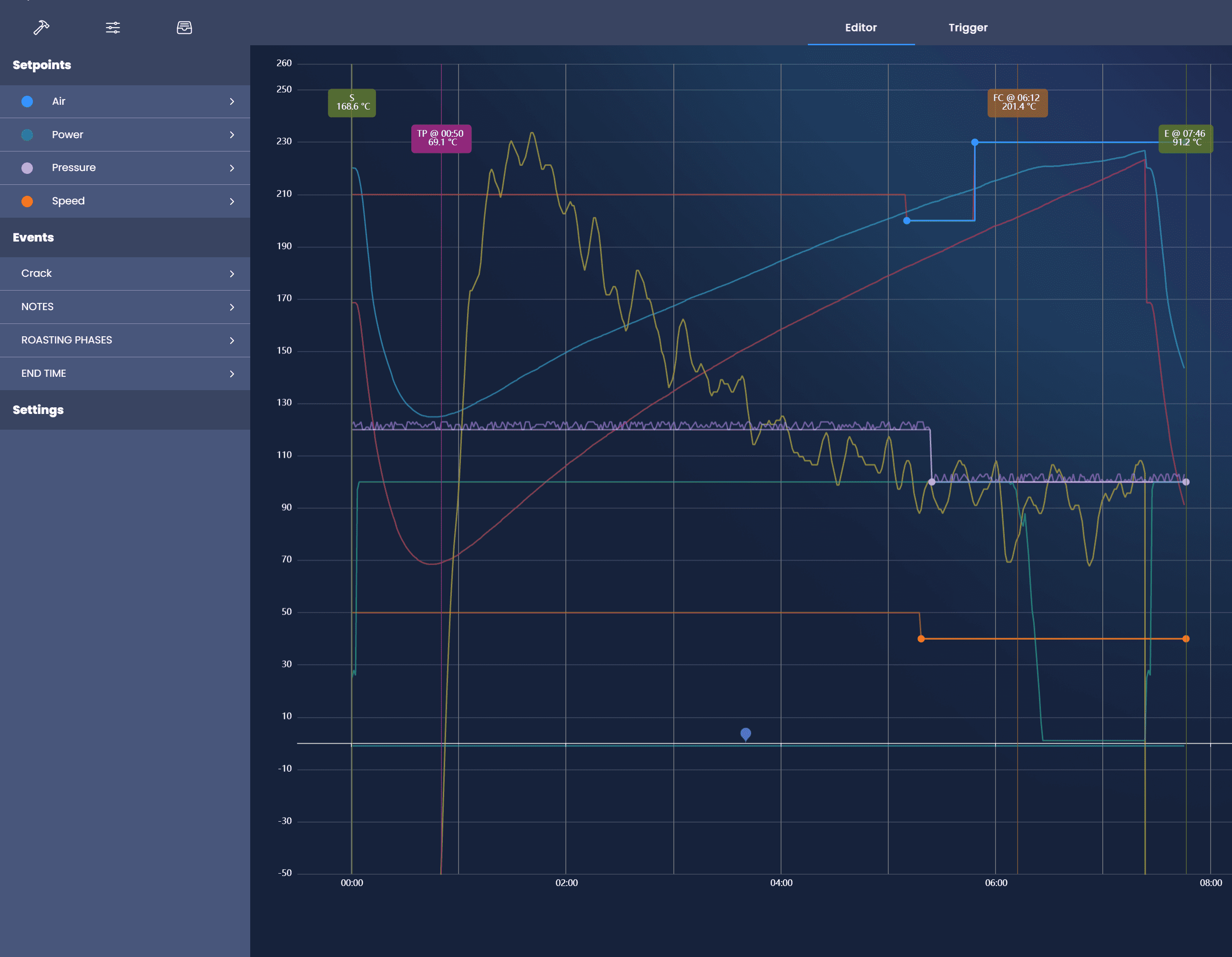

One contemporary roaster shared his simple and basic philosophy about designing and launching coffee blends using his preferred approach: “To create great coffee blends, you need great coffee components.” Quite recently, we had a lot of fun, and we encountered some challenges designing a blend for one of our clients. We did all the work at the roasting and cupping lab of Boot Coffee Campus using our Giesen roasting machines and an assortment of green coffees from all around the world. We started by roasting all candidate components to a range of final roasting degrees varying between 15% and 22% roast development time.

Then we cupped each component individually. We continued using the so-called “wet blending” method by measuring out small amounts of coffee extract and creating possible blends right at the cupping table. The preferred combinations were then repeated as blends using the actual roasted beans. The preferred house blend had a recipe of 45% Guatemala Antigua, 35% Colombia Huila and 20% Ethiopia Sidama Natural. Not too long before the official launch of the blend, the coffee shipment from Colombia got delayed significantly. We had to scramble to find a suitable replacement. Fortunately, we found an excellent alternative from the Capucas cooperative in the Copán region of western Honduras. The fruit tones of this washed Capucas contributed magnificently to the final flavor profile. In the end, our client was really happy. The blend became one of their bestsellers!

Willem Boot

Willem Boot is a roasting consultant and trainer and founder of Boot Coffee Campus in San Rafael, California. He is also one of the Giesen Ambassadors. Visit www.bootcoffee.com.