How the Moisture of Green Coffee Beans Affects the Roasting Process

by Willem Boot

One of the factors that plays a critical role in the roasting process is the moisture of green coffee beans. In this blog, we will focus on this factor and explain its effect. We’d like to emphasize that coffee roasting can become quite complicated; at any time don’t hesitate to shoot us an email if you’re confused by the technical language of this blog.

Moisture levels in green coffee

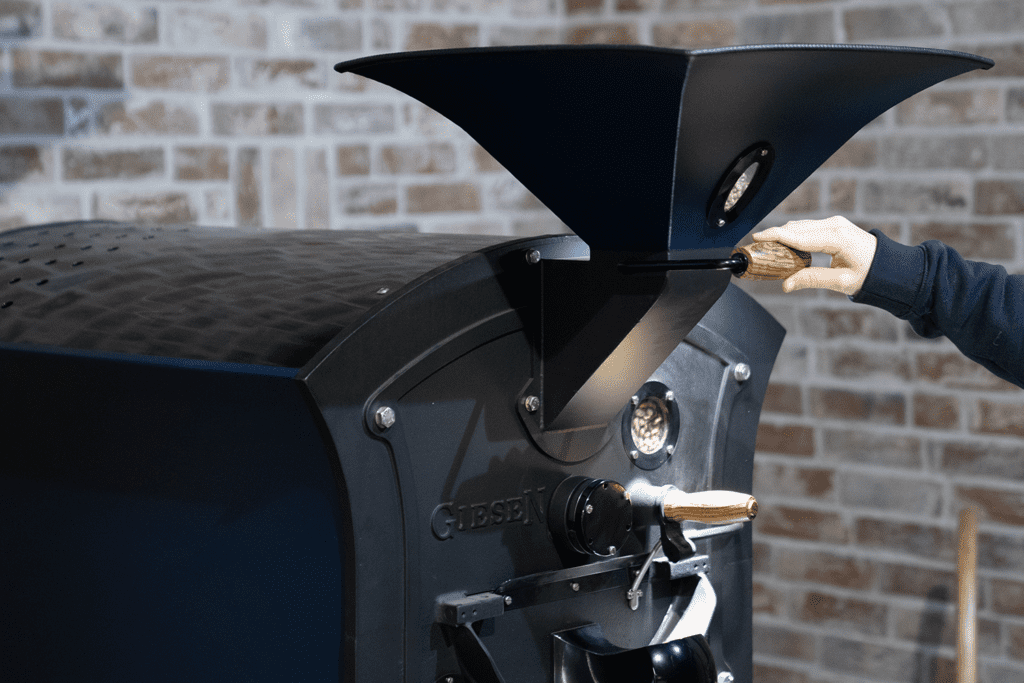

An unprocessed, ripe coffee bean should contain around 45–55% moisture after picking. Processing and drying will then take its moisture content down to 10–12%. Giesen roasters have optimum controls to handle the roasting process of beans with a wide range of moisture levels.

Overall, I recommend the storage conditions of 40 to 70% relative humidity with an ambient temperature of 40 to 70 degrees °F / 21 °C. On top of that, make sure that your green beans are packed well; using Grainpro bags or similar. Depending on how the green coffee is packaged and stored, the moisture content can vary due to the climate.

So, what’s the deal with the moisture content of green coffee beans? The moisture of green beans is partially free, contained in the cellular structure, and partially bound within the carbohydrate molecular structure of the coffee. During the roasting process, the free moisture will evaporate first and at a later stage, the bound moisture will evaporate.

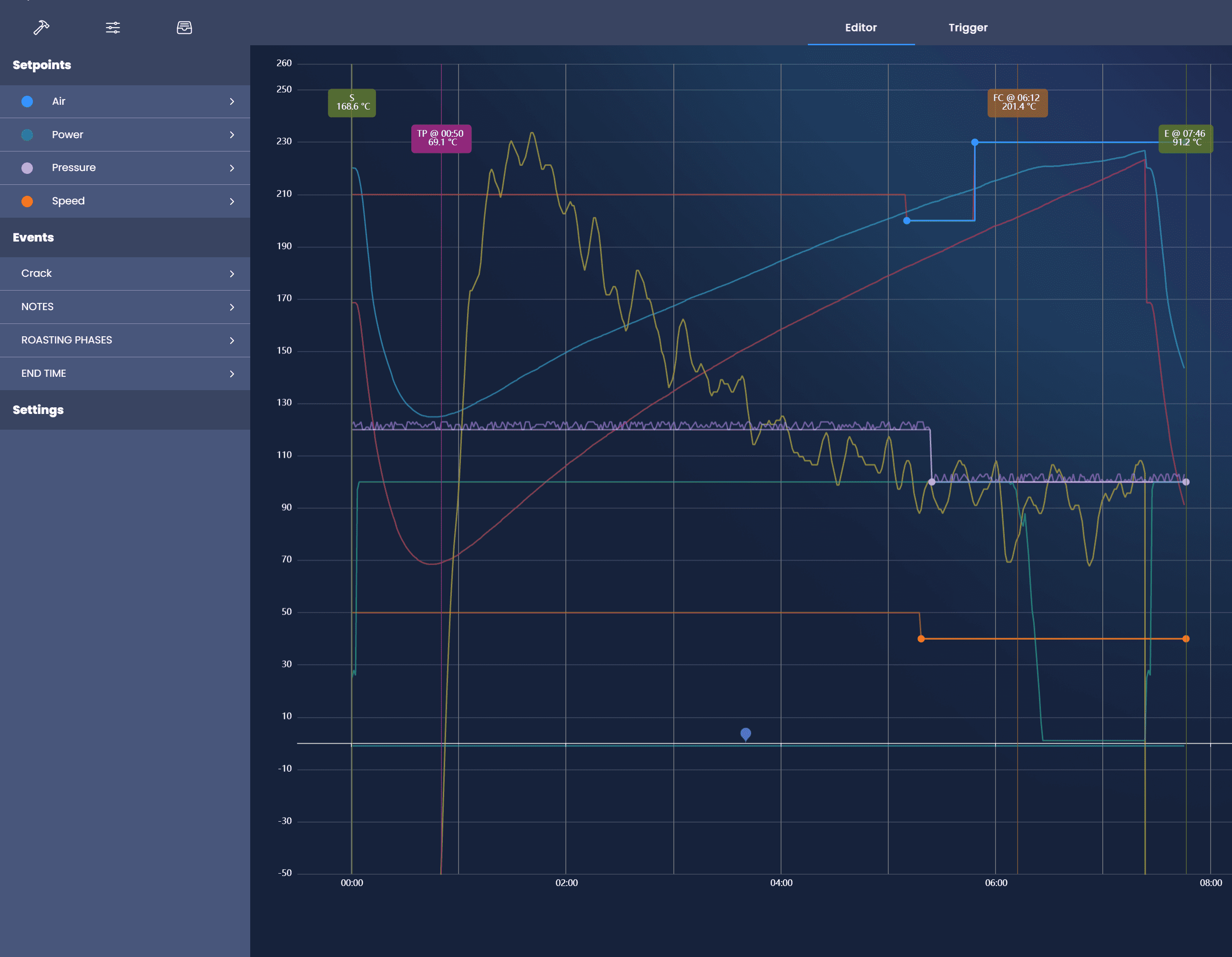

Three-stage roasting cycle

#1

We can summarise the roasting process as a three-stage cycle, beginning with the drying phase. During this period the moisture content of the coffee is reduced to about 2%. This first phase of coffee roasting is driving as much water out of the bean so that the flavor can be developed in a later stage. The free moisture also plays a role in heat transfer during roasting. As soon as the beans are energized with heat, the beans’ moisture conducts this heat throughout the bean. When the internal bean temperature approaches 212 °F / 100 °C, the free moisture starts evaporating.

#2

In the second phase, from 280 °F / 137 °C to 350 °F / 176 °C coffee beans develop their specific aromas and flavors through the chemistry changes caused by the so-called “Maillard reactions”. Towards the end of the second phase, almost all free moisture has evaporated. The length of the second phase depends on the selected roasting profile and specifically on the amount of heat that was applied to the coffee.

#3

During the third phase of the roasting process, the caramelization process induces chemistry changes which cause the development of the appreciated and distinct aromas and coffee flavors. The Giesen roasting technology allows the roaster operator to navigate through these 3 essential phases consistently and with an optimum level of control. Now, get ready for some additional technical information, which we also cover during our upcoming monthly Giesen webinars.

Moisture affects the duration of a roast

Beans with a moisture content of less than 10 percent have reduced free moisture content and will tend to roast much faster, especially in the first phase. In this case, the roaster operator needs to change the roasting profile by charging the beans at a lower heat level and maintain a lower amount of energy supply (fewer BTUs) during the first roasting phase. Roasting trial and error is the key to find that perfect profile.

Beans with a high moisture content (fresh crop coffees can have moisture content in excess of 14 percent) often require that the roaster operator includes a pre-drying phase before starting the first phase of the process.

How to pre-dry

During pre-drying, it is recommended that the roaster maintains a drum temperature of 300 degrees °F / 148 °C. This removes the excess free moisture.

Join us at the upcoming Giesen Webinar on May 29th at 9 am Pacific time. We will discuss a variety of technical questions regarding the roasting process with your Giesen roasting machine. I am wishing you health and wellness!

Best regards, Willem Boot

Monthly Giesen Webinar:

Join us live on every last Friday of the month at 09:00 Pacific Time (PT)

Or 18:00 Central European Time (CET).

Dieser Beitrag hat 2 Kommentare

How to maintain a humiditof 10 to 12% humidity for coffee seeds storage.Relative humidity is in %.Humidity is by grains per pound of coffee or by volume.

Hi there, to keep the humidity in your storage unit constant, you have many different options. Of course, the best would be if your space already naturally has the desired humidity. If this is not the case, I recommend that you do some local research into your conditions and how to adjust them if necessary.