Coffee roasting is a delicate art and science that requires precision and expertise to bring out the best flavors and aromas in every batch. However, even the most skilled roasters encounter challenges along the way. This results in coffee roasting defects. Roasting defects can significantly impact the flavor and overall quality of your coffee beans. Let’s explore some common coffee roasting defects, their causes, and how we can identify and prevent them.

Scorching: causes and prevention

We characterize scorching by burnt spots on the flat surfaces of coffee beans, which result in a smoky or ashy flavor in the brewed coffee. This defect can occur when you expose the beans to a higher than ideal charge temperature in the roaster. Other factors can contribute to scorching. Lower density beans, with a softer bean composition are more prone to scorching. Natural process coffee beans are also at risk of scorching during roasting due to their higher sensitivity to heat. Natural process beans usually require a longer and slower drying phase and development time compared to washed coffees. Additionally, a roasting machine with a slower rotating drum or overloading the drum with too many beans can also cause scorching. When you overfill the drum, it hinders the movement of the beans and reduces airflow.

Tipping: identifying and addressing burn marks

We characterize tipping by burn marks that are located at the tips or edges of the coffee bean. It shares a similar flavor profile to scorched coffee. The cause of tipping can be attributed to a charge temperature that is too high, often combined with higher heat levels during the roasting process. Tipping is also influenced by the shape of the coffee beans. Moisture evaporates more quickly from the tips due to the exposure of the tips to the hot surface of the roasting drum.

Internal scorching: managing moisture distribution

Internal scorching is one of the roasting defects that can occur during the roasting process when the moisture inside the coffee beans is not evenly distributed. Green coffee beans consist of a complex cellular structure, with more than half a million individual cells. During the production cycle of green coffee beans, improper drying practices can lead to an uneven distribution of moisture within the beans. When you apply relatively high roasting temperatures, these areas with lower moisture content are susceptible to scorching. To prevent internal scorching, we recommend to exercise caution at the beginning of the roast. Lower the initial charge temperature. This allows for a more gradual and controlled increase in temperature, reducing the risk of scorching the internal parts of the beans where less moisture is present. By ensuring a more even distribution of moisture within the beans, you minimize the likelihood of internal scorching, which results in an optimal roast.

Over-roasting: recognizing and avoiding bitterness

One of the most noticeable characteristics of over-roasted coffee beans is their intense bitterness. We lose the delicate balance of flavors of roasted specialty coffee. Because the excessive heat breaks down the sugars and natural oils present in the coffee. This leads to a burnt and bitter flavor profile. Furthermore, over-roasted beans often lack a vibrant, balanced acidity and a balanced, sweet aftertaste. Another consequence of over-roasting is the loss of the bean’s natural origin characteristics.

Quakers: unveiling hidden defects post-roast

Quakers, although not recognized as one of the genuine coffee roasting defects, can only be detected after the roasting process. They appear indistinguishable from other coffee beans before roasting. Quaker beans typically result from inadequate soil conditions and insufficient nutrient supply during cultivation, which impedes the development of sugars.

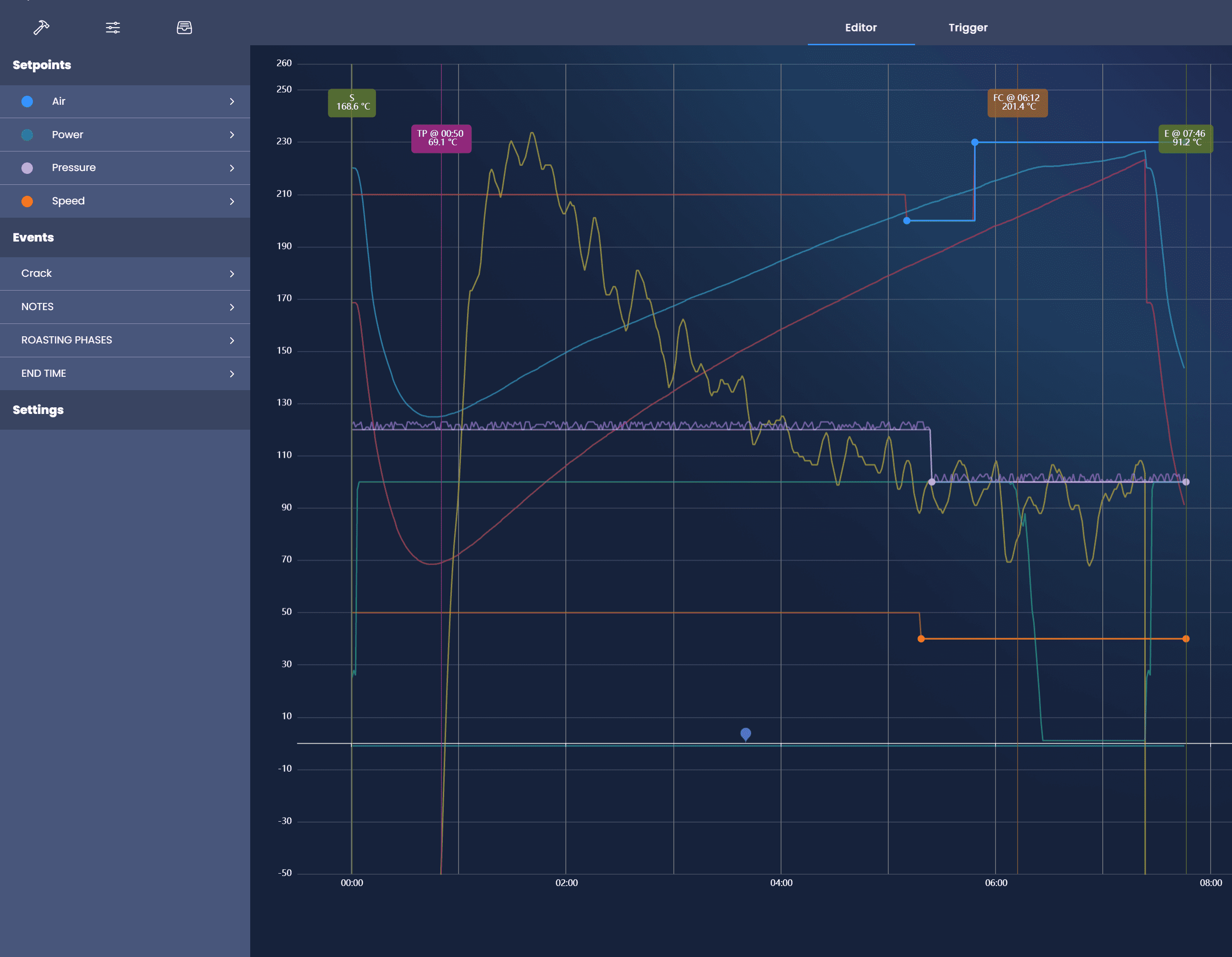

Baked beans: preventing underdevelopment

To prevent coffee beans from becoming baked, it is important to avoid a low Rate of Rise (RoR) during roasting. Baking can occur when the bean temperature increase is less than 2 degrees Celsius per 30 seconds. Also when the roasting time from the start of the first crack to the end of the roast takes more than 2 minutes. To avoid this, we reccommend to roast the beans at a higher temperature and somewhat more rapidly.

Conclusion

When coffee beans have a green or grassy taste and flabby acidity, it can indicate that they are underdeveloped during the roasting process. This defect can often be identified by a distinct lighter color on the inner layers of the roasted beans. This occurs when the exterior of the beans reaches a higher temperature during roasting compared to the inner layers, resulting in an uneven rise in temperature. Underdevelopment often occurs when trying to achieve a lighter roast, as roasters may be overly cautious about over-roasting the coffee. To prevent under-developed beans, make sure to continue the roasting process at least 45 to 60 seconds after the start of the first crack.

More information on coffee brewing, roasting or any other coffee-related subject? Make sure to subscribe to Behind the Roast to get exclusive access to the newest articles and video’s! Click this link to subscribe.

Giesen Coffee Roasters