In the monthly Giesen webinar, Willem Boot, David Sutfin, and Marcus Young cover topics various topics related to coffee roasting. Also, we see Willem Boot visiting the Giesen factory in the Netherlands. The topics we focus on in this Giesen webinar: The unique features of Giesen roasters, an interview with Davey Giesen / Marc Weber, a factory tour, tips to plan and expand your roasting operation, and how to convert and use your preferred profiles for your Giesen machine. We also did a live roasting session with Marcus Young. What follows is the recording and a summary of the Giesen Webinar #4 of the 28th of August 2020.

This webinar is recorded in the Netherlands, where Willem stayed during this live stream and was visiting Giesen HQ. Together with Marcus Young, the campus director at Boot coffee, Willem will help you unlock some of the misunderstandings and mysteries in roast profiling. Marcus and Willem together have half a century of coffee experience. They did a deep dive into roasting, quality management and cupping and continue to develop their coffee knowledge.

What are we going to focus on in this Giesen webinar #4:

- Starting and expanding your roasting operation

- Visiting Giesen HQ; an interview with Davey Giesen / Marc Weber and a factory tour

- Translating roast profiles

- Live roasting session

Starting and expanding your roasting operation

Many people that are planning on entering the coffee roasting business share the same question; what type of roaster should I begin with? Giesen offers a wide range of machines that have various capacities. However, when talking about a roaster it’s very important to consider all other types of equipment as well. First things first; start off by looking at your facility and the available space you have. It’s important that all other pieces of equipment you need to have the needed space as well.

Looking at your facility, you need space for the following activities:

- Shipping and receiving goods

- Storing your green coffee – make sure your green coffee isn’t exposed to the heat of your roaster!

- Your roaster and roaster equipment (destoner, conveyer, cyclone, smoke abatement and ventilation)

- Staging and storing your roasted coffee

- Weighing, packaging and grinding your coffee

- Office space

When looking at your facility, be prepared on the specifications your machinery needs. For example, when you are in the orientation phase for a bigger roasting machine, make sure your facility is prepared on the different gas and electrical specifications the machine needs. By planning this in advance, you will not be faced with surprises when you have purchased the machine and want to install it.

| Roaster type | W1 | W6 | W15 | W30 |

|---|---|---|---|---|

| Green Capacity | 1.5 | 6.0 | 15.0 | 30.0 |

| Roasted volume (20% loss) | 1.2 | 4.8 | 12.0 | 23.9 |

| Roasted volume per hour (3 batches) | 3.5 | 14.4 | 35.9 | 71.8 |

| Volume per 8 hour day | 28.1 | 114.7 | 287.6 | 575.1 |

Before choosing the machine you want to purchase, take your time to assess your business plan and goals. The capacity you need will grow exponentially when your business takes off. Therefore, do not pick a roaster that’s too small and be prepared for a growing business. Also, keep in mind that a larger machine is not much more expensive in proportion. For example, a W15 is 30% more expensive than a W6, but it has 150% more capacity. So take company growth into account in your orientation phase so that when your company grows, you don’t have to look for a machine with a higher capacity on short terms.

In addition to the equipment as described, you may need to purchase various smaller types of equipment in order to operate your roasting business:

Production equipment

- Coffee grinder

- Certified and calibrated scales

- Weighing and filling equipment

- Coffee scoops and fillers

- Packaging material

- Sealing equipment

- ERP software (Enterprise Resource Planning)

Lab equipment

- Sample roaster

- Color meter

- Moisture / density measuring equipment

Cupping supplies

- Calibrated hot water

- Bowls and spoons

Various supplies

- Cleaning equipment

- Maintenance equipment

Visiting Giesen headquarters

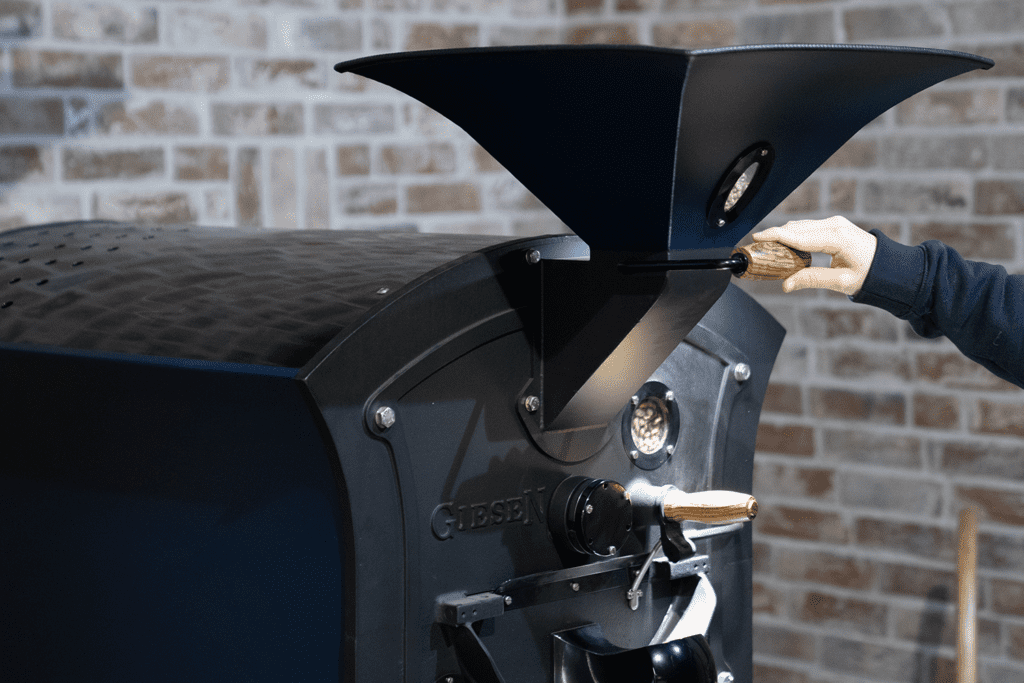

Since Willem visited the Netherlands, of course a visit to the Giesen headquarters could not be missed. It was an exiting day; Willem interviewed Davey Giesen (COO) and Marc Weber (Sales manager) and talked about the unique features and aspects Giesen coffee roasters feature. We took several video’s and made a video summary that you can check out here:

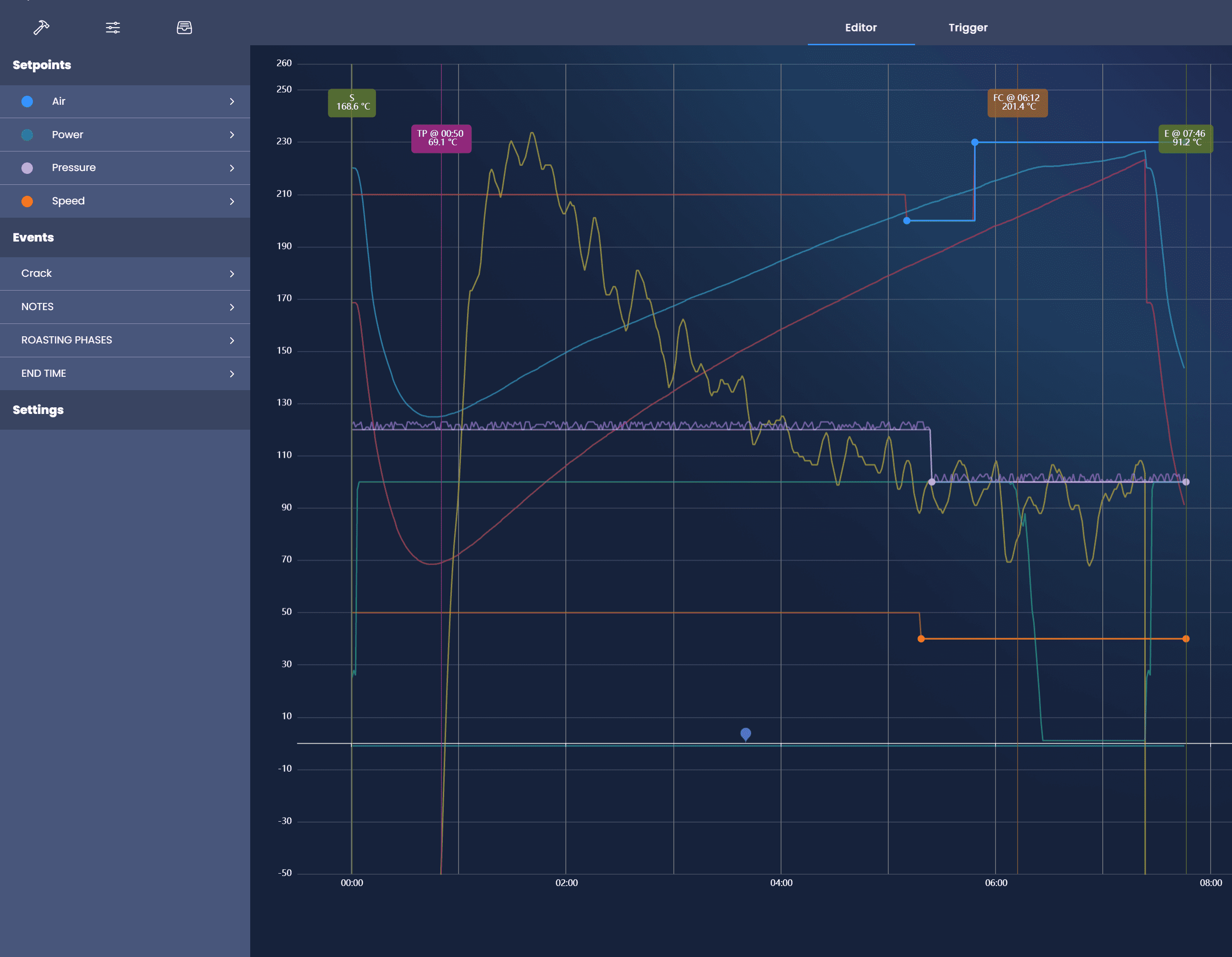

Translating roast profiles

A frequently asked question is how roast profiles can be transferred from one roaster to another. To fulfill this process, it’s mandatory that you fully understand the different parameters that you’re working with when roasting coffee. These are bean temperature (red), air temperature (blue), rate of rise (yellow), and power percentage (purple). To transfer one profile to another machine, you need to understand the phases your coffee goes through. You want to match the coffee roast color at first, and step two is to replicate the different phases on the machine you want to transfer your profile to.

The success indicators of translating roast profiles:

- Understand the different phases

- Matching the bean color

- Understand your application of heat

Basically, the profile on the machine you are translating from is the basis. Then it is up to you to create the same profile on the second machine. This cannot be done by using the exact same settings on the second machine. After all, the machine is bigger, has a higher capacity, and will react differently to the different variables. Check out the webinar video wherein Marcus Young does a live roasting session where the goal is to understand the different variables and see the impact of changes in variables.

Live roasting

Marcus Young demonstrated which techniques he used to follow and replicate a certain roast profile that was created on another machine. Marcus explained which variables you can change to get as close as possible to the roasting profile you are attempting to replicate. The roasting session was driven by the air temperature setpoint, which is just one approach of all possible techniques.

Question and answer:

Q: What do you get with 16% of development in terms of cupping profiles?

A: It’s complicated because roast development and roast color go hand in hand. With this development time, you can expect a quite bright coffee, with hints of fruity flavors. When you would extend the development to about 20%, you can expect an increase in vanilla / caramel / sugary characteristics, but is will all depend on the type of coffee you are roasting.

Q: Does the software do green stock data?

A: No, not currently.

Q: What pressure ranges can you use before the beans will be pushed out of the machine?

A: We recommend not to go beyond 180 – 200 Pa, since a full batch will then result in beans entering the chaff collector.

The next webinar is on 25th of September, where we will cover additional topics related to coffee roasting, and we will do a live roasting session. Of course, there will be plenty of time for Q&A as well.

Check out the Giesen blog articles here.

Cet article a 2 commentaires

Puédese enviar presupuestos de la W1 y W6?

Gracias

Was very constructive