Calculating your coffee companies carbon footprint is a priority for basically all actors in the coffee value chain. The growing impact of climate change on the daily lives of people around the world has driven a badly needed mindset change. The coffee industry cannot ignore the bitter reality of sky-rocketing greenhouse gas emissions caused by economic activities in the coffee sector fueled by the combustion of fossil fuels. Before calculating your company’s carbon footprint, you need to consider how your activities facilitate your company’s overall sustainability strategy.

The journey from tree to cup can cause a significant increase in your company’s overall carbon footprint. This depends on the choices you make as a specialty coffee roasting company. Let’s review some key steps of the specialty coffee value chain which can require significant amounts of energy and carbon fuels.

Key steps that require energy and carbon footprint

First, there’s the cultivation of the coffee trees and all connected choices to use either agrochemical or organic inputs. Second, the processing of coffee cherries to produce green, unroasted coffee beans. Third, the transport and storage of coffee beans from the producing country to the country of consumption. Fourth, the roasting, packing and distribution of the final product and the energy that’s required to facilitate this step. Fifth, the energy needed to brew the coffee to facilitate the consumption of our beloved beverage.

Fully electric coffee roasters

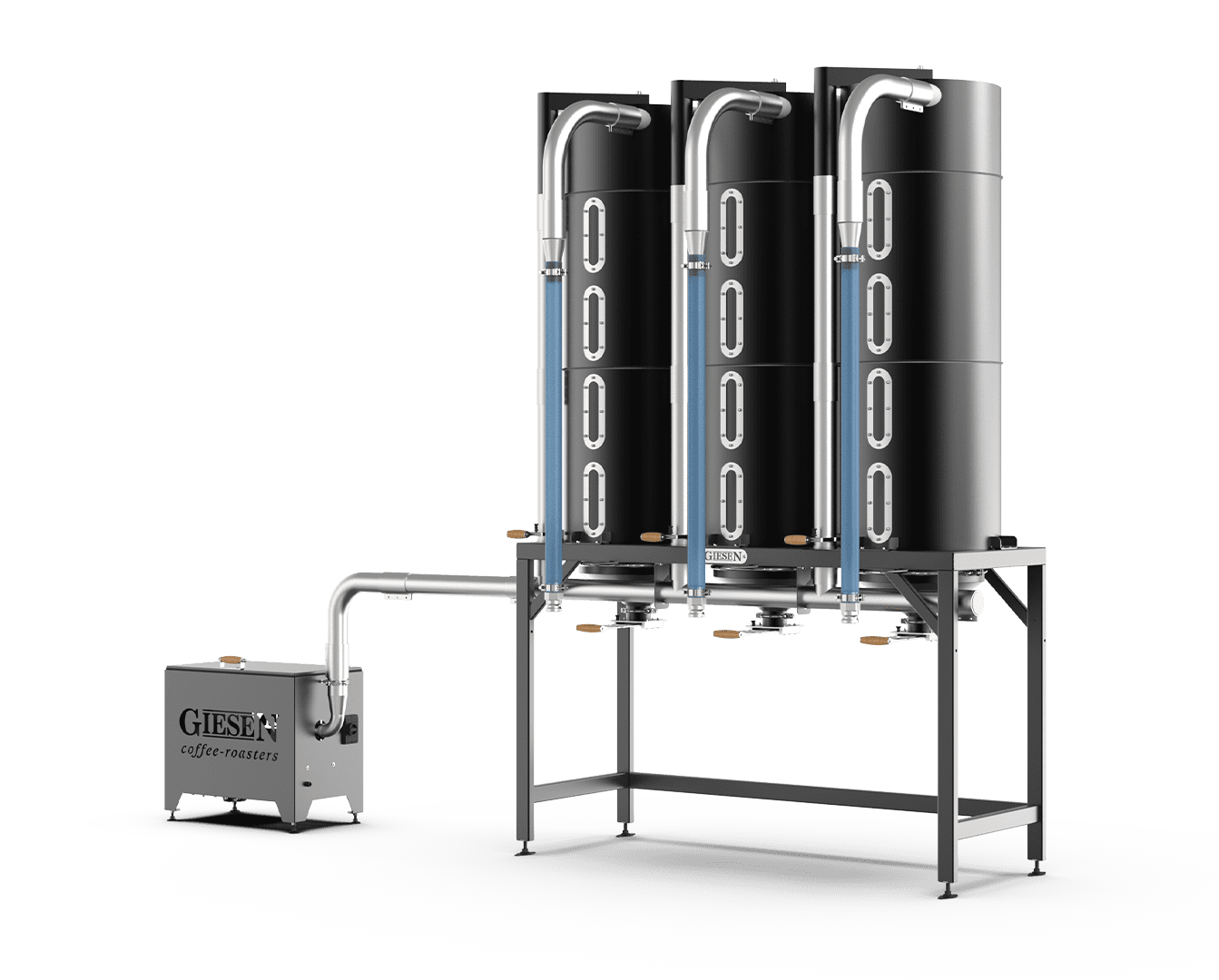

From the perspective of coffee roasting solutions, I’d like to applaud the fact that Giesen Coffee Roasters has been pro-actively promoting the option of fully electric coffee roasters. Take for example the line of fully electric coffee roasting machines. They produce the W1E (up to 1.5 kgs per batch) and the W6E (max. 6 kgs per batch). Designed to significantly reduce the carbon footprint of your company without compromising the final roasting results.

The US-based coffee roaster Deans Bean’s recently claimed to have become the world’s first carbon neutral coffee roasting company. According to their calculations, 17 pounds of coffee generates about 50 pounds of CO2 into the atmosphere. To meet its ambitious goals, Dean’s Beans supported the planting of one tree for every 17 pounds of roasted coffee sold.

Interested to learn more about this important topic and your carbon footprint? Please join our next webinar “Calculating the carbon footprint of your coffee company” on Friday October 29th at 9am Pacific time.

Willem Boot

Willem Boot is a roasting consultant and trainer and founder of Boot Coffee Campus in San Rafael, California. He is also one of the Giesen Ambassadors. Visit www.bootcoffee.com.