Last webinar #19 focused on heat transfer. Willem talked about the benefits of cast iron and all other things you need to know about this material. Besides that, he also takes a look at other materials like steel and gives his honest opinion.

Topics of webinar 18:

- Heat transfer with drum roasters

- The meaning of Cast iron

- Cast iron versus other materials

- Demonstration of the use of cast iron and stainless steel

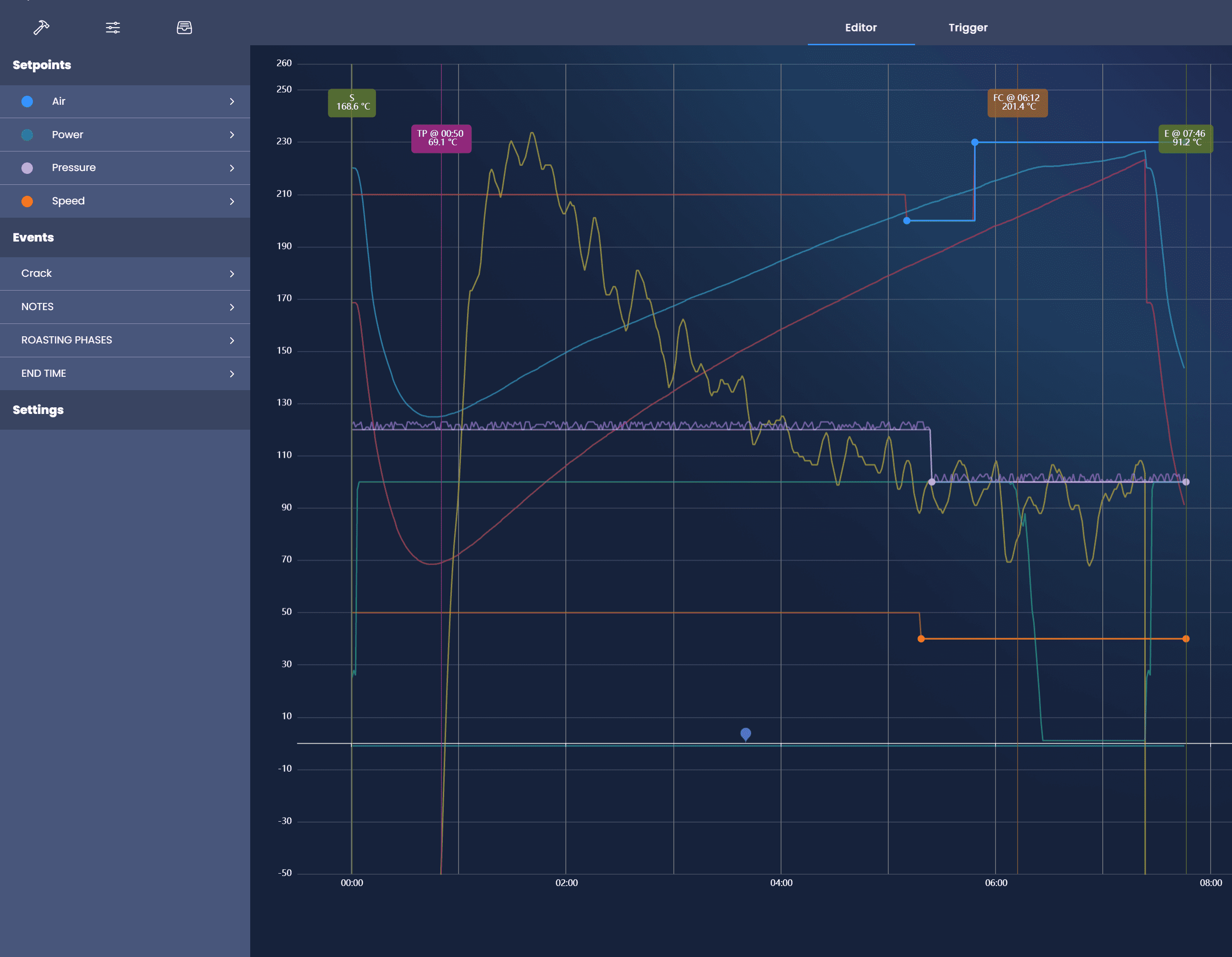

- Roasting with Giesen Profiler

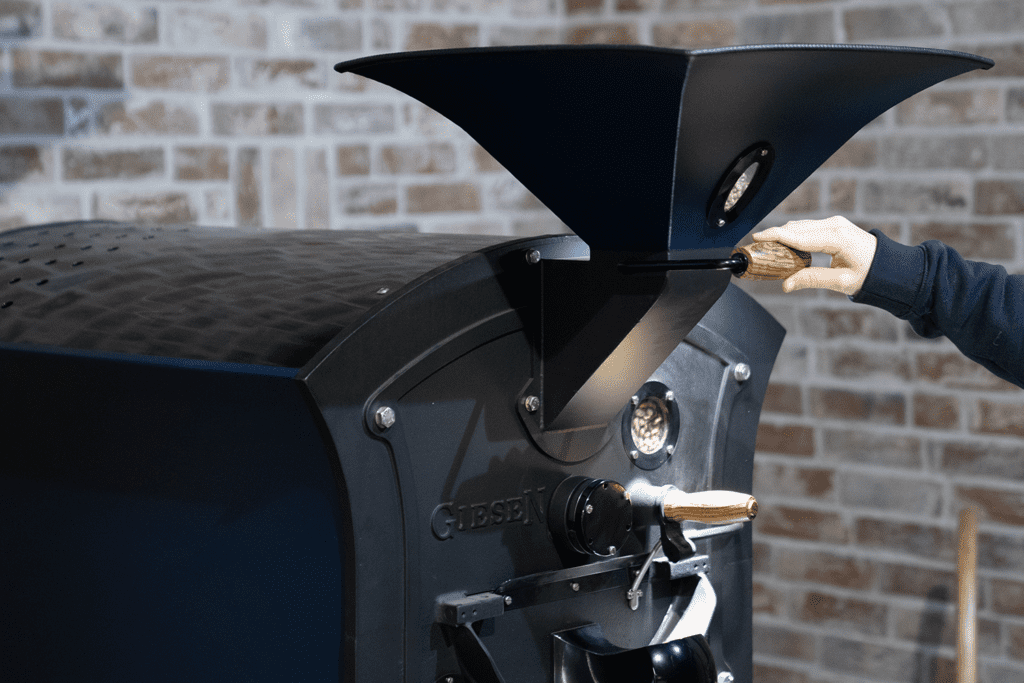

First, I want to discuss some more general things about heat transfer with drum roasters. Depending on the philosophy of the manufacturer, cast iron can be used for various components in roasting machines. This also applies to Giesen roasters where they’ve used cast iron for several components.

Considerations when choosing drum material:

- Thermal conductivity: how well does the material transfer heat when heat is applied?

- Perforations: To enhance convection heat transfer you may want perforations (small holes) in the drum to help the heated air pass through. It is too hard to make so you need to buy it from a manufacturer.

- Workability: How hard is the material to shape and weld? You need special tools, materials, and expertise to weld stainless steel and cast iron is usually cast to shape.

- Thermal expansion: how much will the material expand when heat is applied? If it expands too much you may stress weld and damage the bearings if the drum is rotated on an axle with journal bearings. In that case you may want to consider thrust bearings.

- Corrosion resistance: how much will the material oxidize under normal operation? In most cases the outside of the drum will be of a resistant material to prevent corrosion under normal conditions, or it will develop a protective oxide layer. The inside of the drum will be protected by the bean oils.

TheThere are certain considerations made to the architecture of the roasting drum. Giesen also choose cast iron for some parts of the drum. There is a myth that exists about roasting machines. And that is that to my knowledge, there are no roasting machines that have drums that are only made of cast iron. As far as I know, that just does not exist. When it comes to drums, they have cast iron components in combinations with steel.

Conduction, convectie and radiant heat

When it comes to the roasting process, we have conduction, convection, and radiant heat that can all play a potential role in the roasting process. There are very view roasting machines that try to effectively use radiant heat because of the fact that radiant heat is basically heat by electromagnetic waves. When we talk about the heat transfer of Giesen roasting machines, we’re dealing with a combination of conduction and convection heat.

Conduction: Transfer of heat from one object to another via direct contact. You heat up the drum, and that heat is passed on through the drum, to the beans. Or from bean to bean.

Convection: Transfer of heat via the medium of fluid or gas. Natural duo too hot air rises and forced via a fan.

Radiant: Transfer of heat by electromagnetic waves (can’t see or control).

During the roasting process, the heat can be endothermic, which means absorbing heat energy from the environment. This phase usually lasts until a moment before the start of the first crack and after that, this heat becomes exothermic. Now the beans start to release the heat.

Cast iron versus other materials

- Carbon content

Pure elemental iron is too soft to be useful in most applications, and therefore more useful when it’s alloyed or mixed with carbon. In fact, carbon composition is the main distinction between cast iron and steel. Cast iron typically contains more than 2 percent carbon, while cast steel often contains between 0.1-0.5 percent carbon.

- Castability

Cast iron is relatively easy to cast, as it ours easily and doesn’t shrink as much as steel. This means it will readily fill the complex voids in a mold and requires less molten materials to do so. This flowability makes cast iron an ideal metal for architectural or ornate ironwork structures such as fencing and benches.

- Compressive strength

Compressive strength is the ability of a material to withstand forces that would reduce the object’s size. This is opposite to forces directed at pulling a material apart. Compressive strength is beneficial in mechanical applications where pressure and containment are factors. Typically, cast iron has better compressive strength than steel.

- Heat diffusion

Stainless steel does not have good heat diffusion characteristics because of its low thermal conductivity. Heat diffusion of stainless steel is inferior to mild steel and especially to cast iron.

Like to see a demonstration where Willem uses both a cast iron pan and a stainless-steel pan? Watch the webinar.

Check out the other Giesen blog articles and webinar summaries here.